Sensor-driven

sustainable packaging.

9 out of 10 top brands trust Masitek smart sensors to improve packaging line performance, detect damage, and reach their sustainability goals.

The industry choice because it works.

Rapid Detection of Container Damage

Masitek in-line sensors are ideal for problem-solving interventions and early detection of performance trends related to packaging damage. Insight from the sensors can guide regular line checks, pinpointing areas prone to damage, and the optimal line speeds to avoid breakages.

Using in-line sensors ensures consistent equipment performance and facilitates effective collaboration with suppliers by sharing actionable data.

Sustainable Packaging Success

Masitek’s in-line sensors revolutionize sustainable packaging design practices. Our sensor technology enhances supplier collaboration and directly influences the design and optimization of bottles, cans, and secondary packaging with real-life data.

Insight into the vulnerabilities of container designs, production damage resulting in waste, and the early detection of process inefficiencies ensure packaging lifecycles are sustainable and environmentally considerate.

Optimal Line Performance with Smart Sensors

Enhance production efficiency with Masitek’s in-line sensors. Our packaging sensor technology monitors operations from the perspective of your containers to ensure every aspect of production is optimized.

From reducing container stress for increased operational speed to fine-tuning settings for new container types, our sensors keep your line running at peak efficiency. Experience the dual advantage of safeguarding product quality and reducing inefficiency for every process from design to delivery.

How smart in-line sensors work

Exact replicas of your containers are deployed on your production line to accurately measure your container’s experience during processing.

Exact replicas of your containers are enabled with smart sensors.

Smart in-line sensors travel through the line to monitor the entire process.

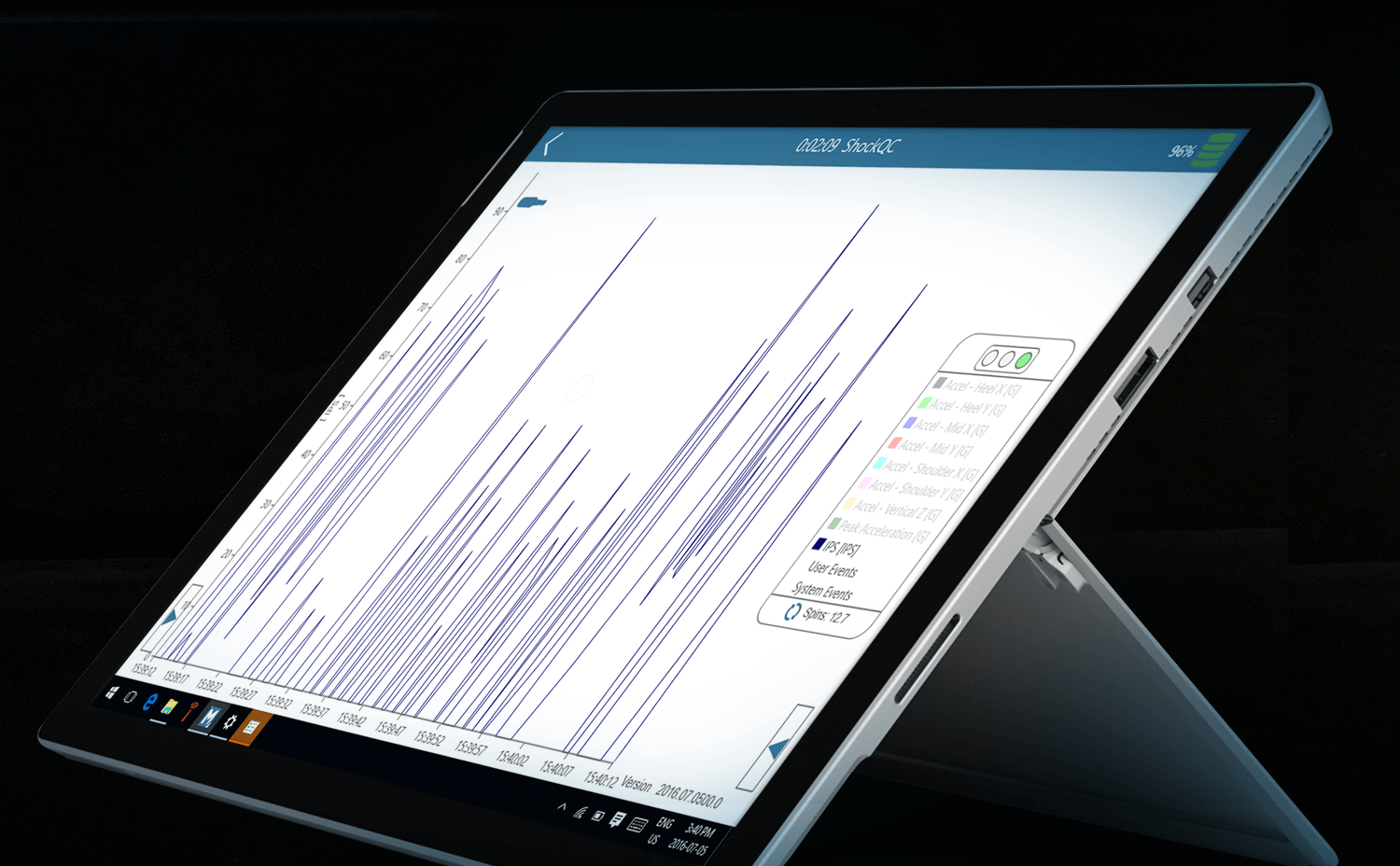

Indicators such as impact, IPS, G-force, scuff, vertical pressure, spin and tilt accurately measure a container’s experience during processing.

Wireless, location tracking Bluetooth beacons pinpoint the location of damage and opportunities to improve line efficiency.

Each run is configured on the solution tablet and corresponding app, with integrated photo and video capture to document notable events.

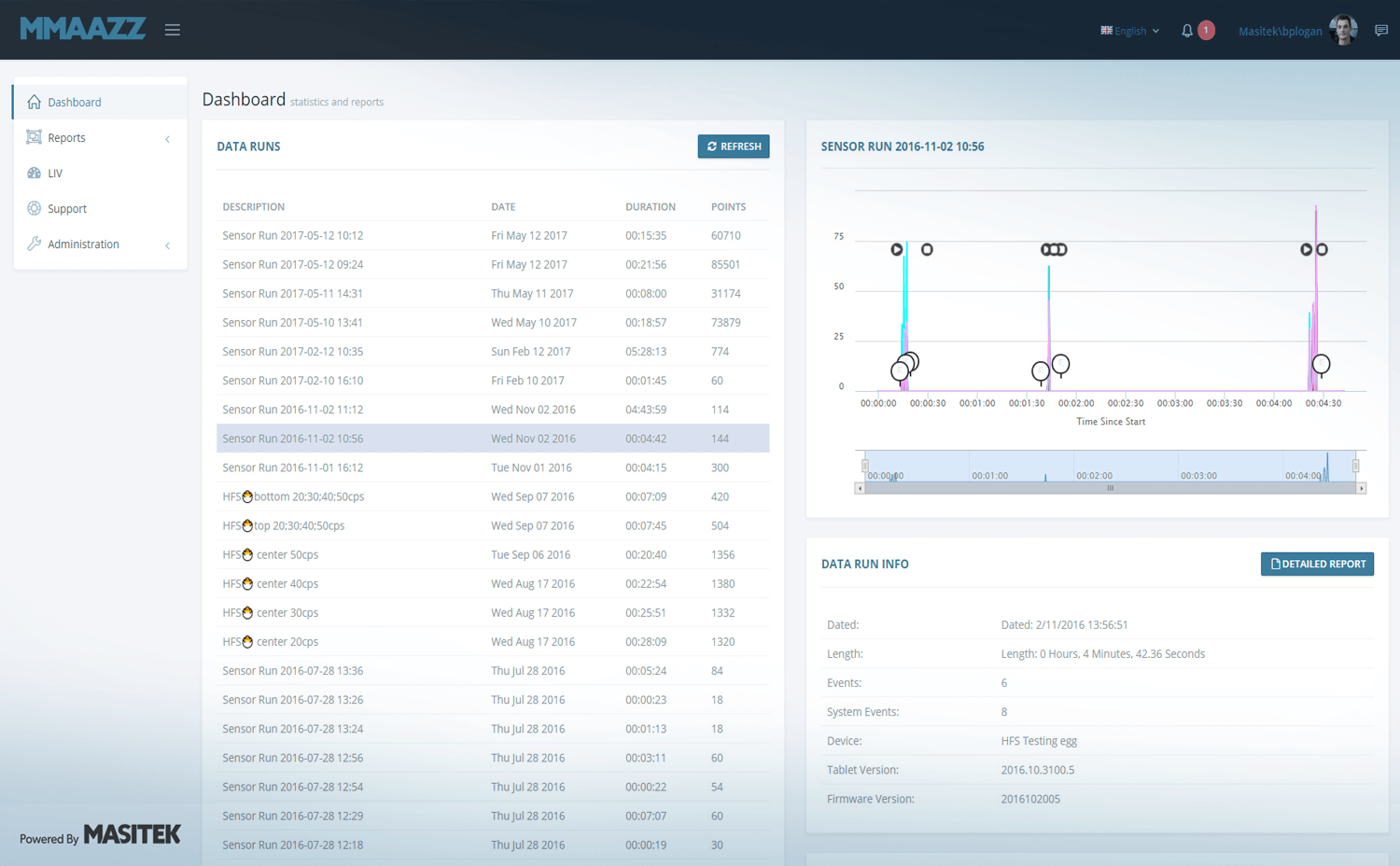

An easy-to-use web interface can be used to compare data runs and generate reports from anywhere.

Hear it from industry leaders

Carlsberg uses smart sensors globally to pinpoint breakage.

Carlsberg Group

Heineken increases the number of filling cycles from returnable bottles.

Heineken

O-I uses in-line sensors to remediate issues and test new glass on the line.

O-I Glass

ShockQC™ is a very useful tool that we use to diagnose issues on customer filling lines. Having the ability to measure impacts in-line, wirelessly in real time has provided data to improve our customer’s filling operations

Michel Alesi, Vice President of Operational Excellence

O-I Europe

Find the source

of packaging damage

on the line.

From The Blog

Understanding Impact Force: The Key to Accurate Measurements

Accurate impact force measurement in bottling and packaging is crucial for grasping the root cause of shocks,...

Protecting Your Shipments: The Ultimate Guide to Shock Sensors for Shipping Success

Introduction to Shock Sensors for Shipping Shock sensors for shipping are transforming the way food and beverage...

IPS – What It Means & Why it’s a Vital Measurement for Glass Packaging.

In the bottling industry, the IPS measurement, which stands for Inches per Second, plays a pivotal role in ensuring...